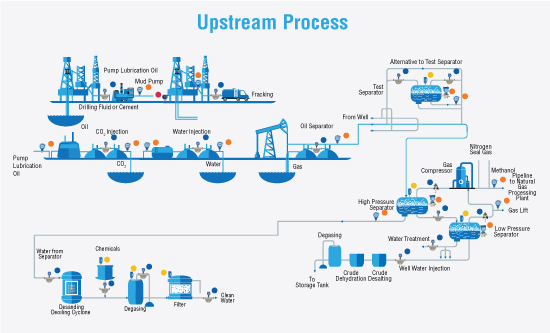

UPSTREAM PROCESS

The Upstream Oil and Gas markets is also known as Exploration and Production (E&P). Exploration mainly consists of crude oil and natural gas fields, along with the drilling of wells process. Production is subsequently operating the wells to produce crude oil and raw natural gas. Wet gas measurement, Multiphase, Custody and Allocation metering are all associated with this market segment. Tek-Trol offers a range of products to suit this segment ranging from Differential pressure Cone meters, venturi meters, Coriolis meters, Pressure and DP transmitters together with many more metering products to enhance the clients measurement needs

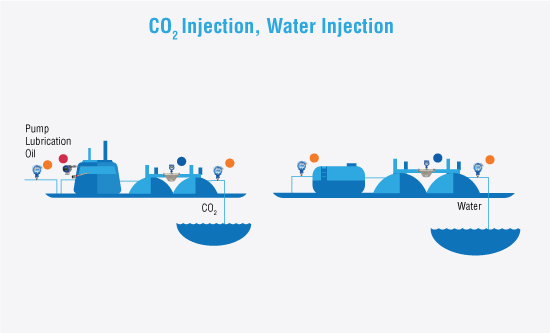

- CO2 Injection, Water Injection

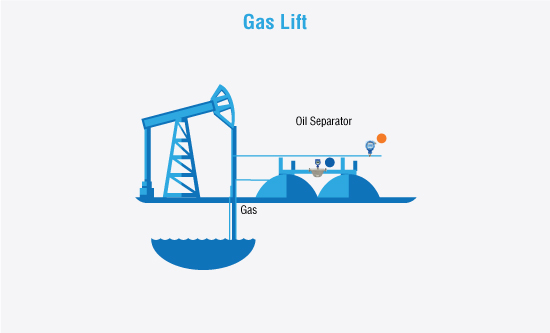

- Gas Lift

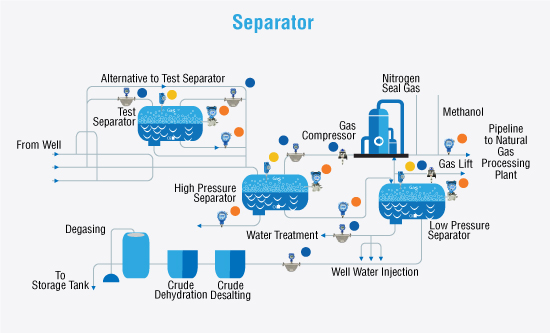

- Separators

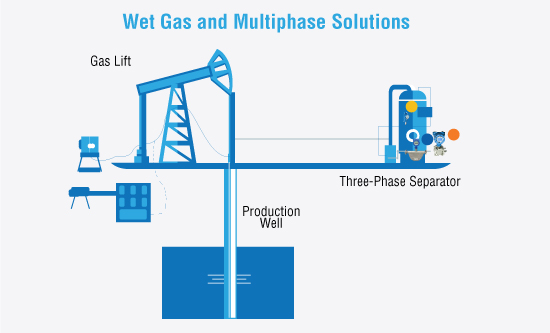

- Wet Gas and Multiphase Solutions

- Water Treatment

CO2 INJECTION, WATER INJECTION

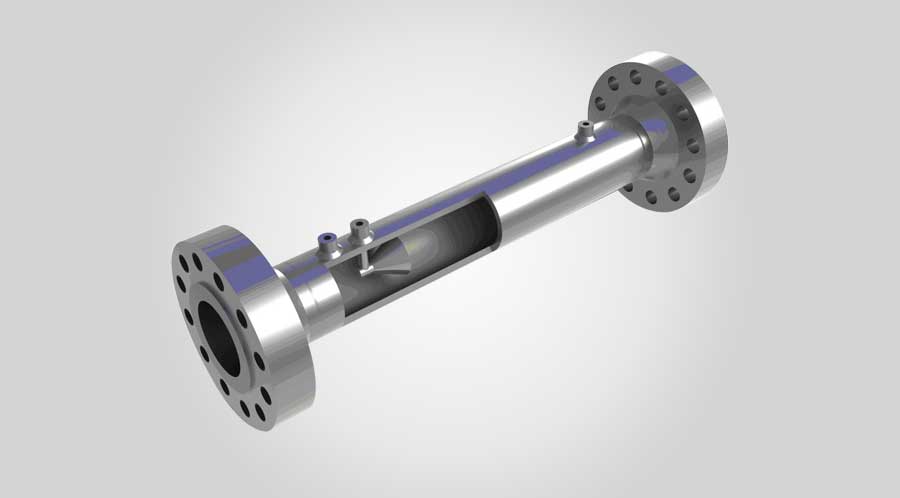

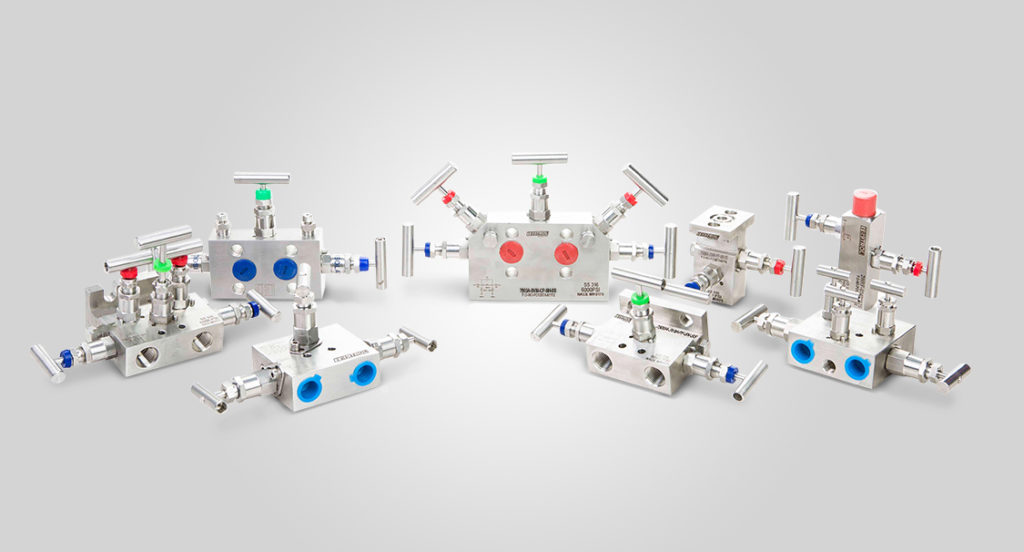

After a well hydraulic fracturing process is completed, primary production can begin. Primary production refers to crude oil that is recovered naturally from a producing well without artificial means or enhanced oil recovery (EOR). EOR stimulation methodologies are used to recover hydrocarbons during later stages of the well / reservoir life. This improves the amount of oil that can be gained due to natural pressure decline with time and a reduction in the oil slate at well locations. Various techniques are used such as: Waterflooding, Chemical Flooding, Immiscible Gas Injection, Miscible Gas Injection, Thermal Recovery and other Chemical Methods. Water Injection is a secondary EOR production process, known as waterflood. The Water Injection process is used in both onshore and offshore developments. Water Injection is implemented under pressure into a reservoir or well base to encourage oil production replacing lost pressure after the primary stage has occurred. Tek-Trol offers a range of high-pressure flow meters for accurate and reliable measurement of liquids for well water injection, including our DP meters, Coriolis, Ultrasonic and Electromagnetic flow meters. Co2 Injection methods mentioned above helps to recover oil that remains in the reservoir after primary or secondary methods are exhausted. This process also helps to improve volumetric sweep and oil displacement efficiencies. Injected Co2 may become miscible or remain immiscible with oil, depending on reservoir pressure, temperature, and oil properties such as viscosity. The miscible CO2- EOR process is preferred because it can achieve higher recoveries than the immiscible process. Tek-Trol Pressure and Temperature Transmitters help CO2-EOR process implementation due to reliability and quality of manufacture.

Steam Injection is used to stimulate viscous oil production and requires steam quality measurement to make sure that well geology is not damaged (gypsum degradation). Tek-Trol supply a steam quality meter for this application that calculates in real time the density, volumetric flow rate and mass flow rate from 2-meter technologies “Vortex Meter and DP cone meter” in one meter body. The meter is unique and available from Tek-Trol and can accurately measure injected steam to help prevent reservoir degradation!

- Flow Measurement

- Pressure Measurement

- Temperature Measurement

- Accessories

GAS LIFT

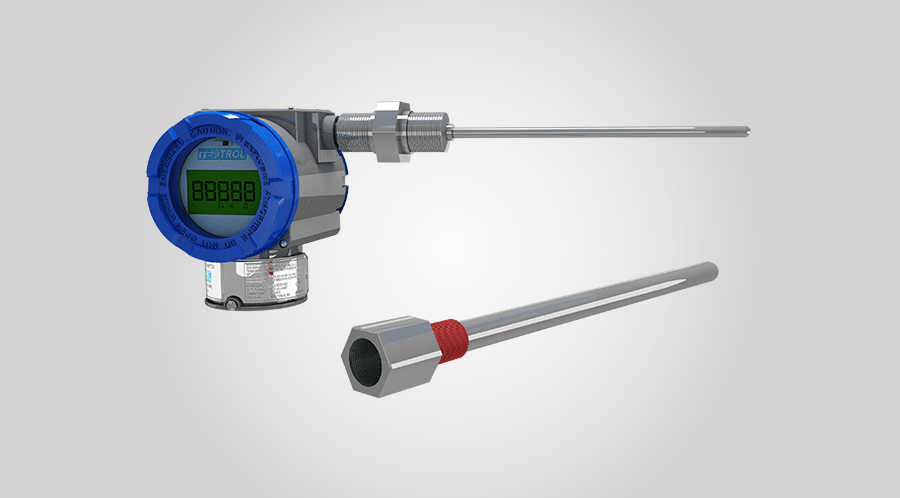

Gas lift is a method of artificial lifting of liquids from a well using an external source of high-pressure process gas supplementing formation gas, to lift well fluids. The principle of a gas lift is to inject gas into the well tubing/bore which reduces the density of the hydrocarbon liquids in the tubing, subsequently bubbles developed by this method apply a “scrubbing” and lifting action on the liquids. Both these factors act to lower the flowing bottom-hole pressure (BHP) at the base of the tubing/well bore. Tek-Trol pressure transmitters are used in this application due to their robustness and reliability.

The injected process gas is usually applied between the casing and tubing. A pressure release valve installed on a gas lift “mandrel” is inserted into the tubing above the packer. These “mandrels” with integral valves can be set at different pressure ranges to improve gas distribution and thus, liquid flow and assist start-ups. The gas lift can also be optimized over several wells using this method of pressure control. The temperature of the Gas Lift Process can also be measured by Tek-Trol supplied High Quality Temperature Transmitters. Tek-Trol also offers a range of high-pressure flow meters for accurate and reliable measurement of liquids and gasses for artificial lift processes of various types including: DP meters, Coriolis Force Flow Meters, Ultrasonic and Electromagnetic flow meters

- Flow Measurement

- Pressure Measurement

- Temperature Measurement

- Accessories

SEPARATORS

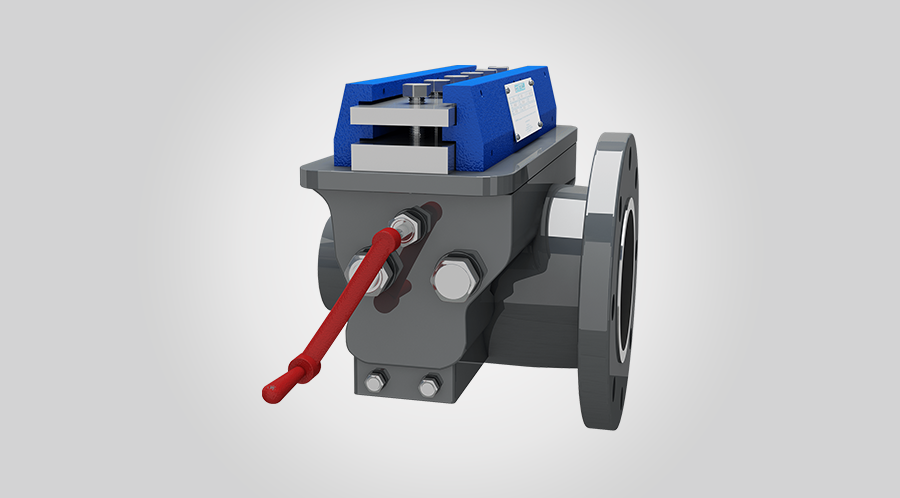

Separator vessels are designed to receive multiphase hydrocarbon-based flows from offshore or onshore pipelines usually from multiple well-head systems ultimately to separate gas, water and liquid hydrocarbons. Crude oil, gas / gas condensates, water, and various contaminants are the main fluid components flowing from these wellheads. The purpose of the production or test separator is to split the flow into desirable single-phase fractions and then measure them using various single phase flow meter types. Tek Trol DP Cone Meters and Venturi Meters can be used to measure separated gas flow whilst Tek-Trol Coriolis meters can measure oil flows together with our range of produced water metering. A liquid control level (retention) is maintained in the separator tank to facilitate hydrocarbon gasses to leave the liquid the gas is measured at the highest point in the tank and any water also to be removed from the base of the tank, oil being taken from a point above the water level in the separator. Separator liquid level (retention time) uses a level controller and level control valve. The traditional level controller consisted of a float on a spring the past. Today a Modern Tek-Trol Guided wave Radar Level Transmitter can be used to control liquid level which is more reliable accurate and can be monitored remotely if needed. As the liquid level in the separator rises, the guided wave Radar senses the level until it closes a switch, which then opens a level control valve to let out some liquid. When the level falls back down to the normal operating level, the Radar system senses this operates a switch which opens again and drives the level valve closed. The gas output rate is controlled because liquid is fairly incompressible and the liquid level in the separator remains constant if the Separator volume / thruput is correctly calculated, the gas above the liquid is contained in an approximate constant volume. As more gas enters the separator, the pressure rises and its measured at the output.

Tek Trol explosion proof (Exd) pressure transmitters are mounted on the separator-gas space or on the outlet-gas piping. This transmitter sends a signal to a pressure-control valve in the gas-outlet piping telling it to open when the pressure is higher than the set point. Pressure-control valves are usually modulating, which means that they gradually open wider as the pressure rises to a value higher than the set point and close as the pressure falls to a value lower than the set point. Separated single phase liquid flow rates can also be measured by Tek-Trol , Coriolis meters , Electromagnetic and Ultrasonic Flow Meters for produced water and oil usually decided by client’s preference.

- Flow Measurement

- Pressure Measurement

- Accessories

- Level Measurement

WET GAS AND MULTIPHASE SOLUTIONS

The Tek-Trol Wet Gas Metering Solution is used to measure significant water/hydrocarbon content in unprocessed the gas streams. Using proven state of the art algorithms and DP measurement devices wet gas liquid loading can be predicted with good accuracy, whilst the same measurement system can be also used to provide controlled based system monitoring/maintenance. The system “Tek Val Sys” is available for any DP gas meter by using the same transmitter set up as the wet gas system. Wet gas measurement of unprocessed gas is useful for : Well management, adjusting water injection rates or gas lift pressures, and allocation measurement. Condition based monitoring saves unnecessary maintenance trips to site and particularly offshore platforms.

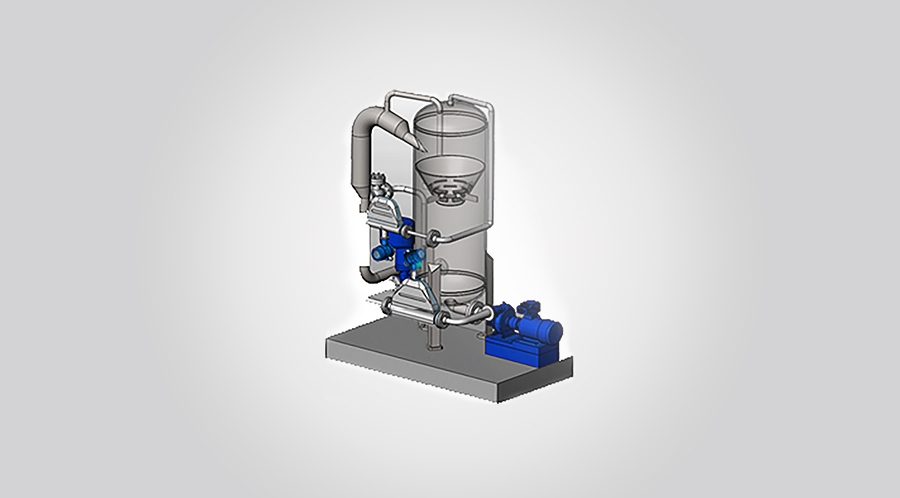

The Tek-Trol Multiphase Metering Solution provides a separate flow data for two liquid phases and provide gas void fraction measurement from a single flow meter. Tek-Trol flow meters, include: Coriolis, Ultrasonic, Electromagnetic, Orifice DP Cone and Venturi meters and many other tertiary products to provide operational efficiency throughout all Hydrocarbon separation and measurement applications. Together with our efficient Hydro-Cyclone Separator a full multiphase / allocation or test separator system can be developed and operated successfully in a small area! The Tek-Trol “Tek-Cloud” IoT Monitoring Solution platform enables connections across a wide range of metering applications such as flow, level, temperature, and pressure.

- Flow Measurement

- Pressure Measurement

- Accessories

- Level Measurement

WATER TREATMENT

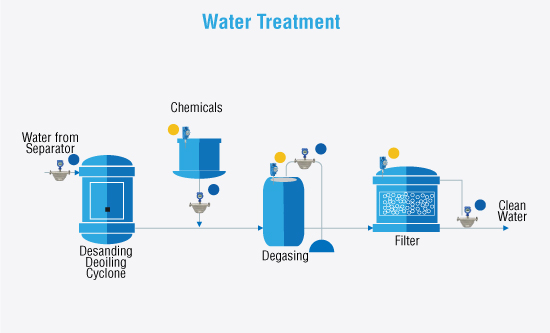

Produced Water is a by-product during oil and gas production and separation processes. When salt water injection is used to provide enhanced oil recovery or increase well pressures, down hole water content increases. Significant percentages of water are present when the field exhibits high water cut values. It is essential to measure produced water flow accurately This water flow can be measured by the Tek-Trol Electromagnetic Flow Meter which is available in various materials to suit the process.

Produced water is considered as industrial waste and needs to be treated by removing contaminants before disposal. Different techniques are used if the produced water is to be re-injected into production wells or into to some other underground formation. This process method includes equipment for the analysis, flow measurement, chemical dosing, and other techniques generally used in produced water treatment systems – including cyclonic separation, filtration, de-gassing, chemical treatment, and flotation. Pressure and Temperature all measured by Tek-Trol robust Temperature and Pressure transmitters!

- Flow Measurement

- Pressure Measurement

- Temperature Measurement

- Accessories

MIDSTREAM PROCESS

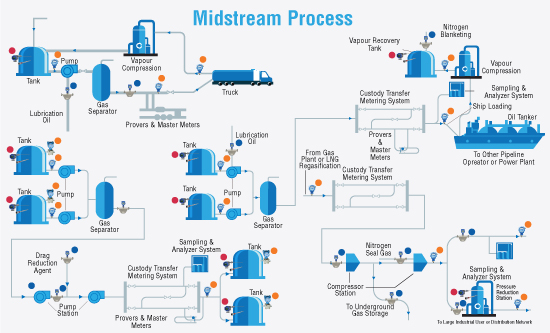

A significant activity of the oil and gas markets is the transportation of Hydrocarbons and their storage, also known as the “midstream” sector of the markets. Gas and liquid pipelines, along with processing facilities, storage tanks, truck rail, ship loading are all associated with this market. Custody/Fiscal metering applies in this market segment, where high value oil and gas products change ownership (custody transfer). In a process plant fluid flow, pressure, temperature instruments and analyzers are all used for custody transfer measurements. Pipeline conditions are also monitored to ensure transportation process safety and leak detection. These flow measurement instruments are installed directly into pipelines or tanks at storage and distribution centers together with tank gauging and other safety interlock systems to ensure that the storage tanks cannot be over/under filled or depleted accidentally..

Tek-Trol provide reliable process instruments and complete measurement solutions such as custody transfer metering skids and analyzers to monitor complete oil and gas transaction methodologies. For pipeline measurement systems, Tek-Trol offers, state-of-the-art pipeline leak detection systems, including high quality measurement instrumentation. For retrofit installations / existing plants, our hi-tech measurement instrumentation can often be incorporated per client requirements.

- Drying, Filtering and Liquefaction

- Natural gas pipeline

- Loading and Fueling

DRYING, FILTERING AND LIQUEFACTION

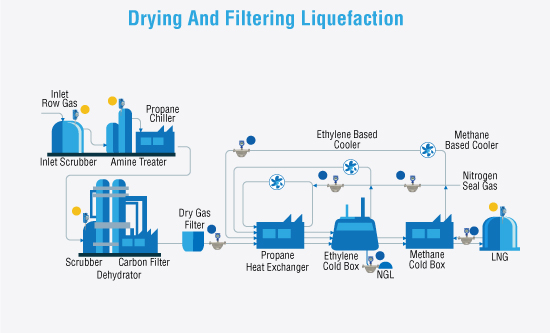

After well-head processing, natural gas is collected and transferred to a liquefaction plant via pipelines. A custody transfer metering skid then can measure the delivered quantity. Before the main liquefaction process begins, various filtration systems and scrubbers are used to dry and remove impurities such as mercury, H2S and CO2. and other contaminants. Analyzer instrumentation determines the composition and quality of the delivered products, after the liquefaction has occurred. During the liquefaction process, various components naturally found in natural gas propane, ethane, methane and butanes are extracted by the producer applicable to contract requirements. These components are then offered as fuels or other uses in the petrochemical markets LNG is produced which has a primary component of methane CH4. and is offered to local and overseas users based on its BTU content. LNG product liquefies at -162°C. Cooling is achieved in one or more liquefaction process. During the cooling operations, ethane, propane, and butane are extracted at various stages, as ‘natural gas liquids’ (NGLs) and are measured and recovered as byproducts. Tek-Trol Temperature Transmitters can be used to monitor the temperature of an LNG Plant.

Once liquefaction is completed, LNG product is stored in large and insulated tanks. These tanks are fitted with Tek-Trol Guided Wave Level Transmitters to help to control both high and low liquid levels. LNG is not usually artificially cooled during the storage period, therefore, the liquefied gas in the tank can boil-off. The boil-off gas (BOG) is then returned back to the liquefaction process, where it can be re-processed. LNG pressure can be measured using Tek-Trol Explosion-proof Transmitters. Tek-Trol provides custody transfer metering systems for natural gas also entering the LNG plant, cryogenic LNG product, and other cryogenic measurement instrumentation plant use . Natural gas flows can be measured by Tek-Trol Coriolis, Clamp-on Ultrasonic meters.

- Flow Measurement

- Temperature Measurement

- Pressure Measurement

- Level Measurement

LOADING AND FUELING

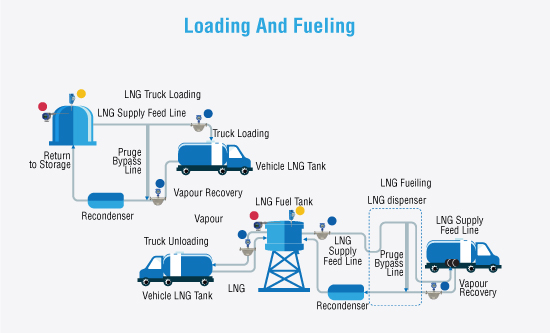

LNG is usually delivered by road tankers or small ships for local distribution to special LNG fuel stations or loading facilities. After that, LNG sold as a fuel for trucks and ships. LNG is a clean product producing emission levels in line with many world-wide environmental policies. LNG bunkering ships are under development, which would refuel the larger ships while they are in port loading or unloading their cargo. Large insulated ships are transporting LNG overseas these vary large ships use LNG boil off to power their engines. During the loading of tankers, trucks or ships, LNG deliveries are monitored by custody transfer flow measurement installations. These special meter systems take account of LNG boil-off gas returned to the storage tank after being re-liquefied.

Custody transfer flow measurement systems also monitor bulk LNG deliveries and smaller delivered quantities dispensed to vehicles and other users at LNG fuel stations. Tek-Trol Ultrasonic and Coriolis Flow Meters with Field Flow Computers can precisely measure LNG fuel dispensing and truck loading. LNG Tank levels can also be measured using our Guided Wave Radar Transmitter in smaller scale LNG applications. Tek-Trol highly accurate Pressure and Temperature Transmitters are used to also control pressure and monitor temperatures in LNG fuel station systems.

- Flow Measurement

- Pressure Measurement

- Accessories

- Level Measurement

- Temperature Measurement

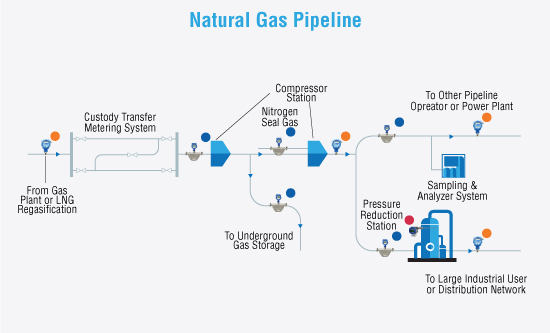

NATURAL GAS PIPELINE

The high-volume natural gas is transported to power plants, LNG liquefaction plants, large industrial users, and city gates through high-pressure transmission pipelines. Compressor stations along the pipeline maintain the flow and line pressure at around 60 bar. These stations use gas from the pipe to power the compressor. If the gas is used in a local gas grid, the pressure would be reduced to around 8 bar at the city gate in a pressure regulating station. This gas transported by different suppliers or delivered to separate users through long-distance pipelines. It is necessary to measure flow in long-distance pipelines for large volume gas precisely. Any inaccuracy would represent a significant financial error, which cannot be tolerated.

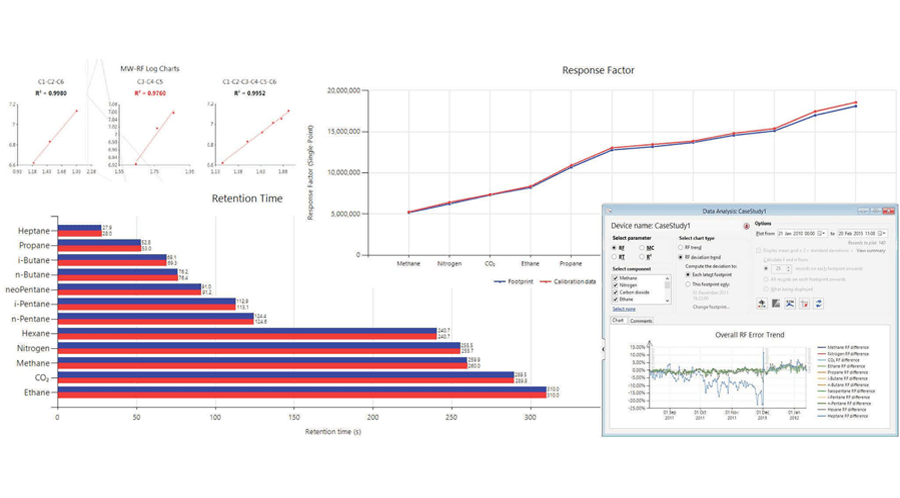

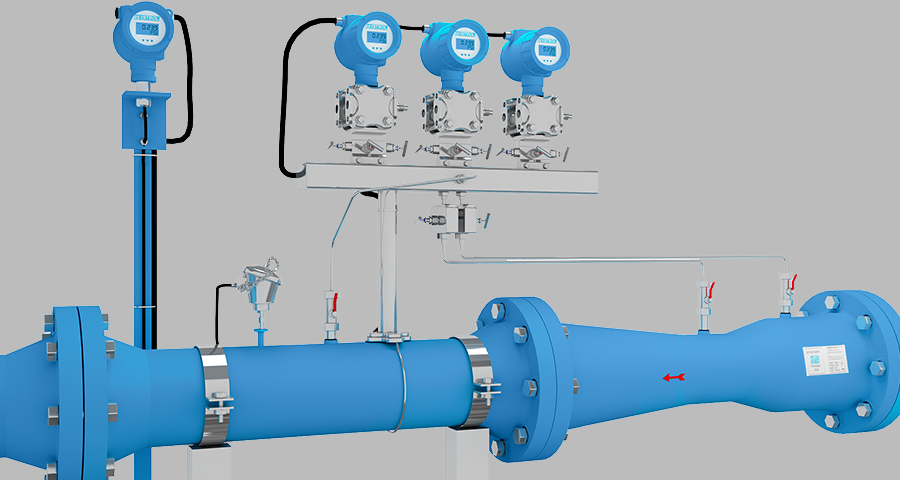

Tek-Trol’s Ultrasonic and Coriolis Flow Meter are specially designed to meet the high accuracy needed for custody transfer measurements with fully engineered metering skids and analyzer. Besides measurements of flow, pressure, and temperature, a gas chromatograph is often installed at each metering station to confirm the calorific value and compressibility of the gas. Additional equipment may include analyzers for dew point, sulfur. mercury and trace oxygen. Tek-Trol’s highly accurate Pressure and Temperature Transmitter are used to control pressure and temperature in LNG fuel station.

- Flow Measurement

- Pressure Measurement

- Accessories

- Solution

- Temperature Measurement

RELATED PRODUCTS