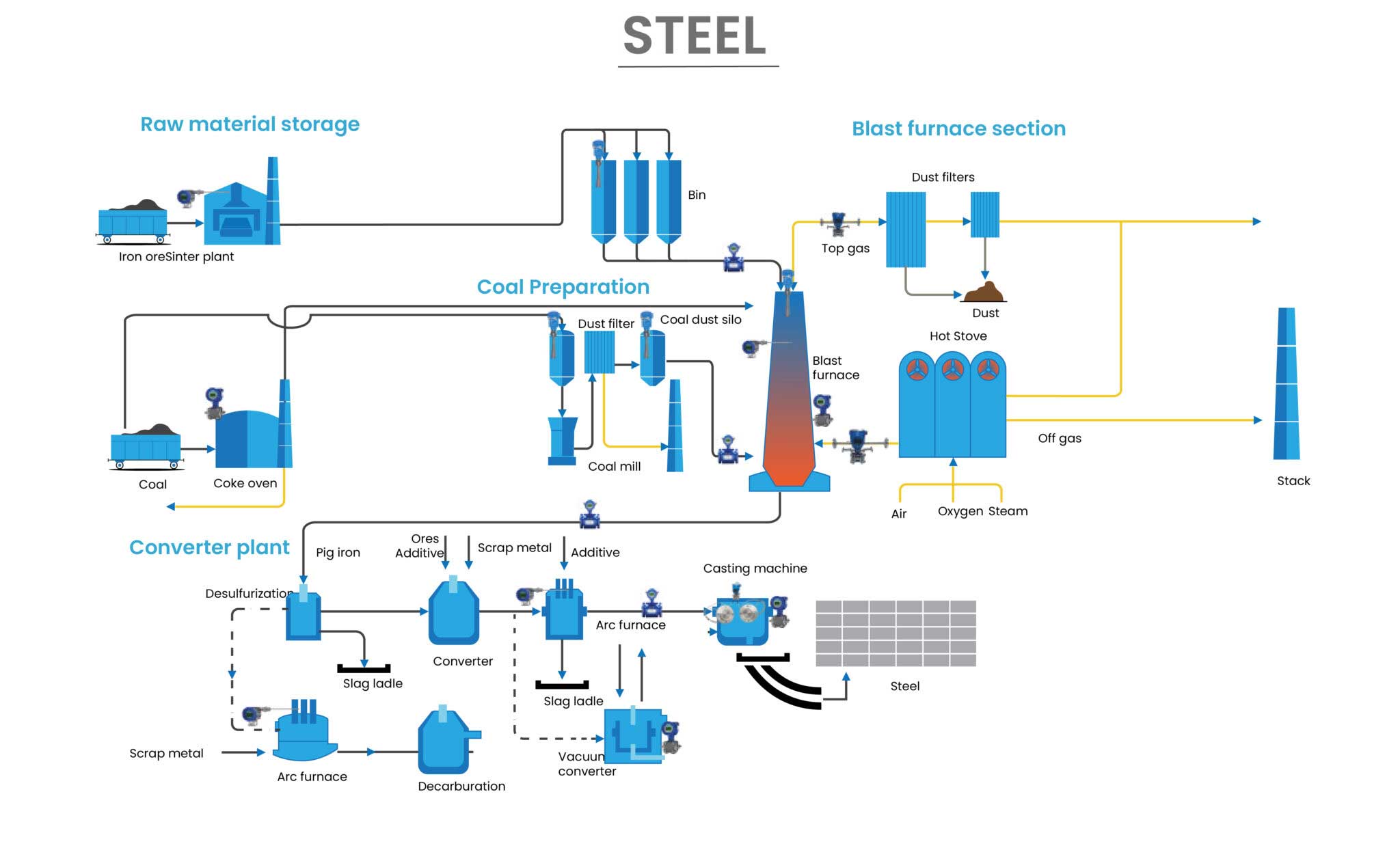

Steel Industry Measurement & Control Solutions

The steel production plant or metal industries process has numerous process and operational challenges in maintaining measurement accuracy, reliability, and asset uptime. Along with these challenges, safety and availability are the main priorities for steel plant operators. All these challenges affect the quality of the product. Robust measurement instrumentation is required to improve quality and safety in steel production. Tek-Trol’s robust instruments ensure a long service life and provide reliable data along with environment-friendly operations. Our products are available for every aspect of these industries, whether exploring and processing expensive metals and coal, distributing bulk solids, or safety-critical utility applications in steel manufacture. Our highly reliable and cost-effective solution helps increase plant uptimes, meet high safety requirements, and enhance productivity.

- Flow Measurement

- Pressure Measurement

- Temperature Measurement

- Level Measurement

- Temperature Measurement

- Level Measurement

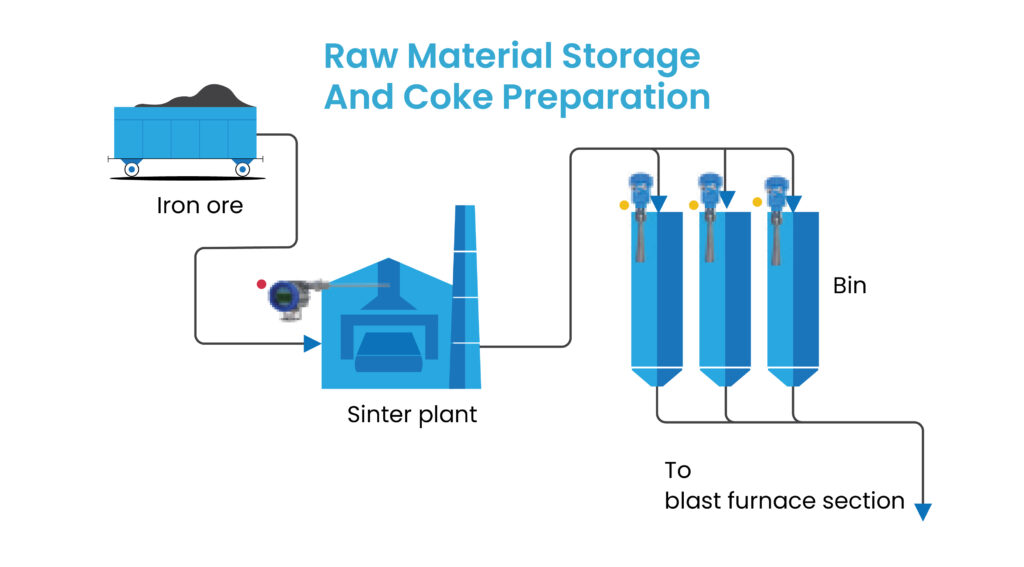

RAW MATERIAL STORAGE AND COKE PREPARATION

The raw material storage is stored raw materials such as iron ore, coal, and limestone produced from mines. Mined ore istransported through conveyor systems to sizeable above ground or underground silos and stored there until used in production. Tek-Trol’s reliable Non-Contact Radar Level Measurement System is used to determine the contents of the silos.This raw material is pass to the sinter plant for further processSinter is an essential process in the feed for the blast furnace process .In this process, a mixture of iron ore fines, fluxes,and different ferrous waste materials such as blast furnace flue dust and oily mill scale combine into a form suitable for use in a blast furnace. After sintering, the hot material is cooled down at a temperature of 150 °C in the sintering cooler. The sintering belt’s feed rate is controlled to ensure that the material is thrown off at the end of the sintering belt. The thickness of the material on the sintering belt has to be continuously and accurately measured by Tek-Trol’s Non-Contact Radar Level Transmitter to achieve adequate cooling and Tek-Trol’s Explosion-Proof Temperature Transmitter monitored the temperature of the sintering process.

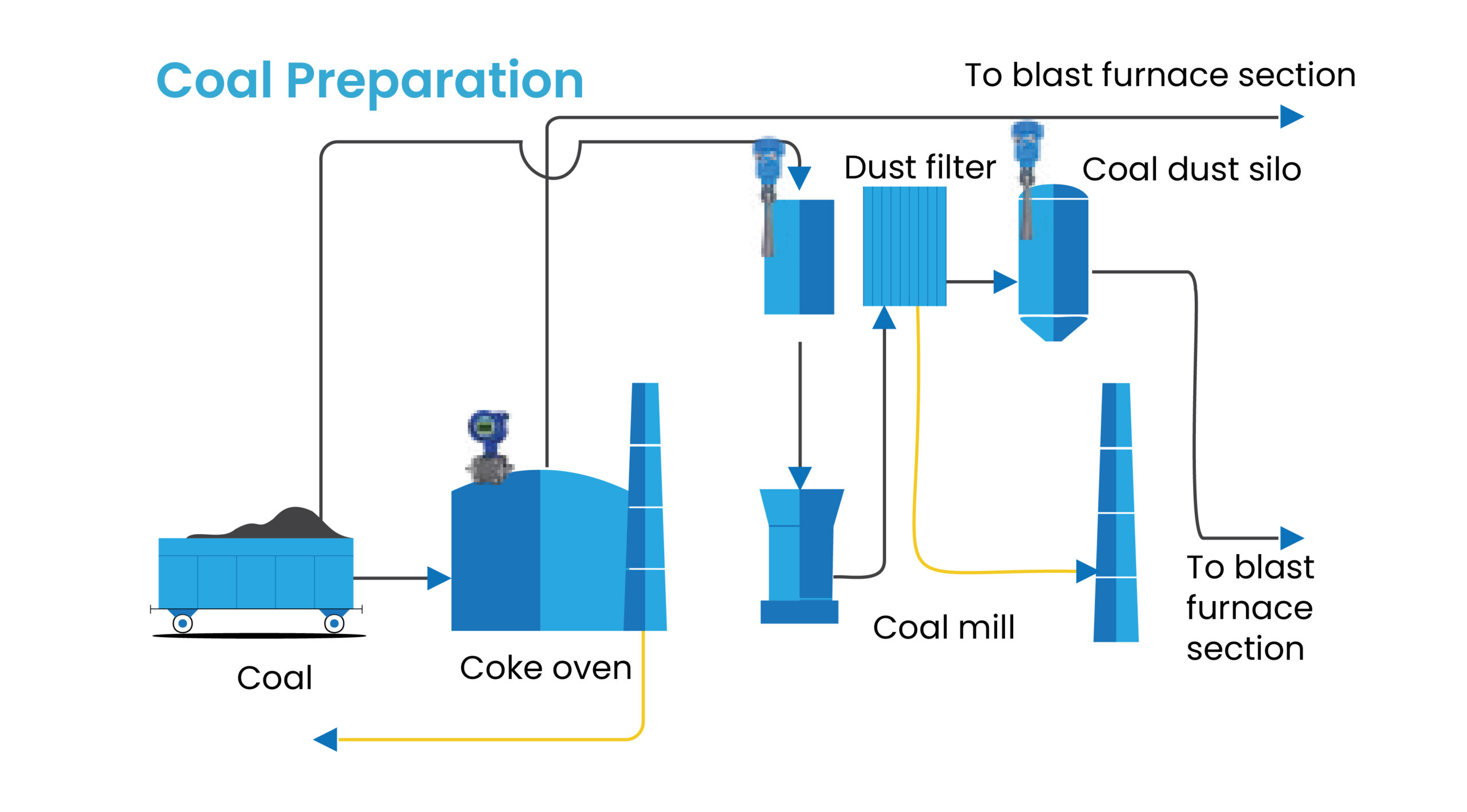

COAL PREPARATION

- Pressure Measurement

- Flow Measurement

- Level Measurement

- Pressure Measurement

- Temperature Measurement

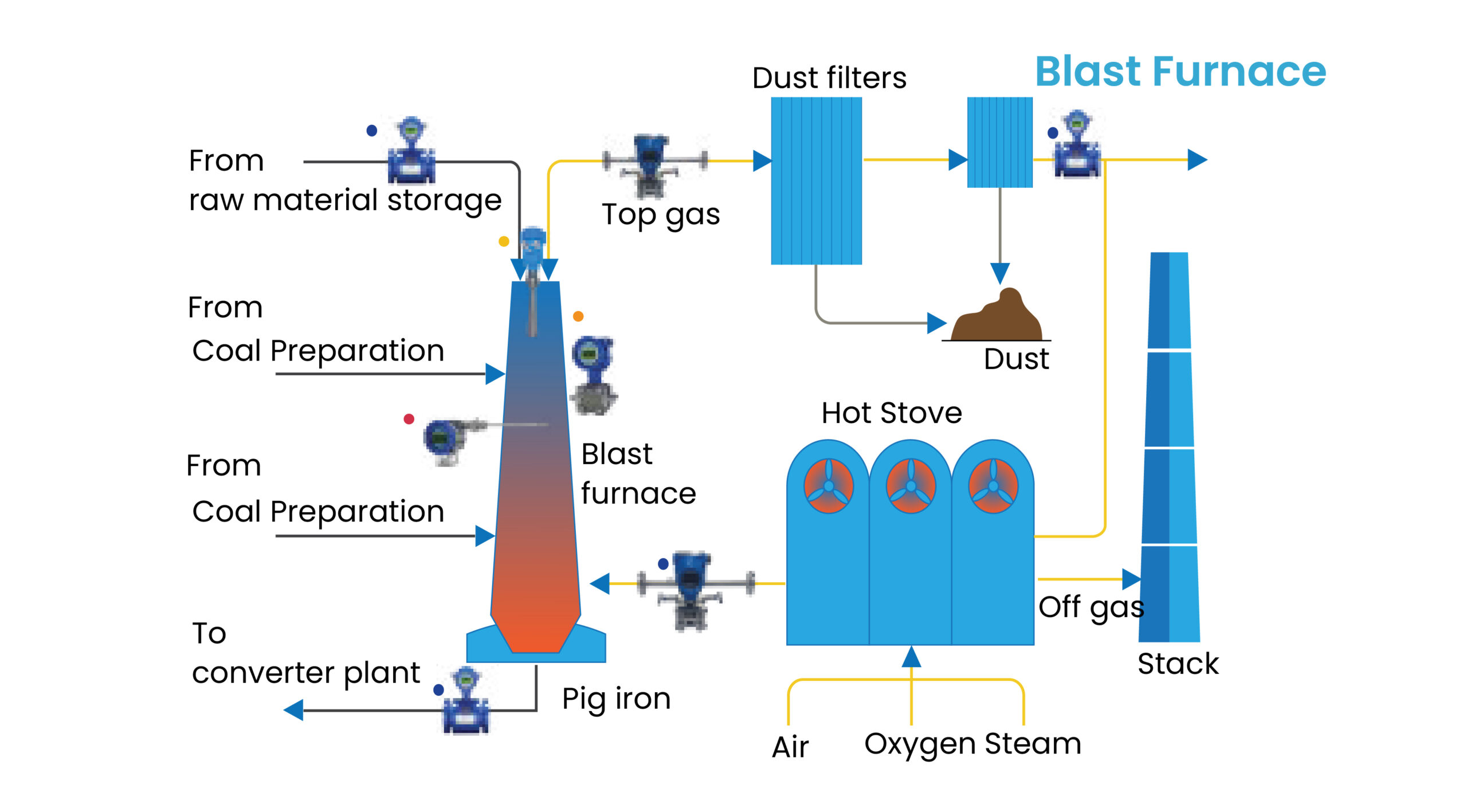

BLAST FURNACE

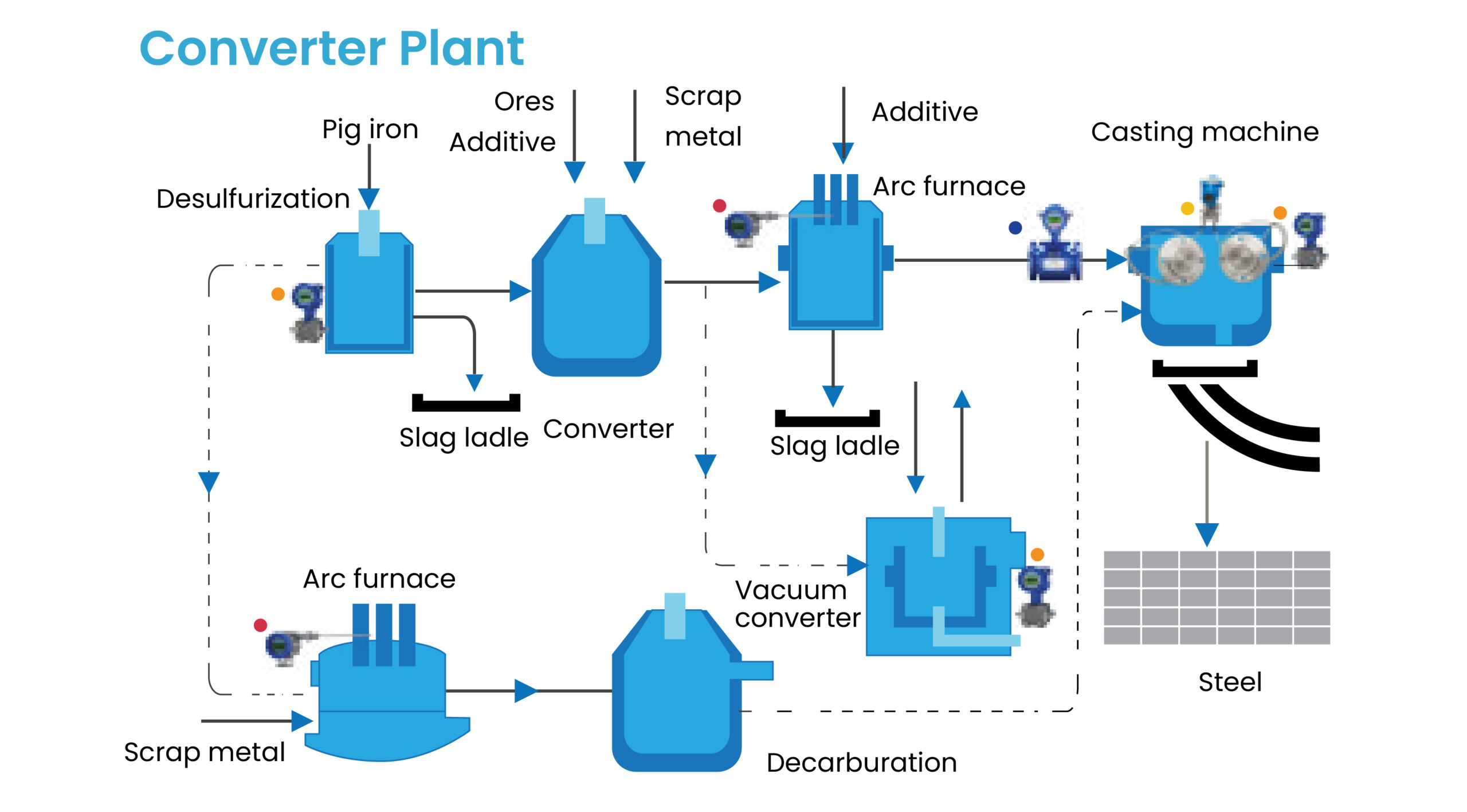

CONVERTER PLANT

- Flow Measurement

- Level Measurement

- Pressure Measurement

- Temperature Measurement