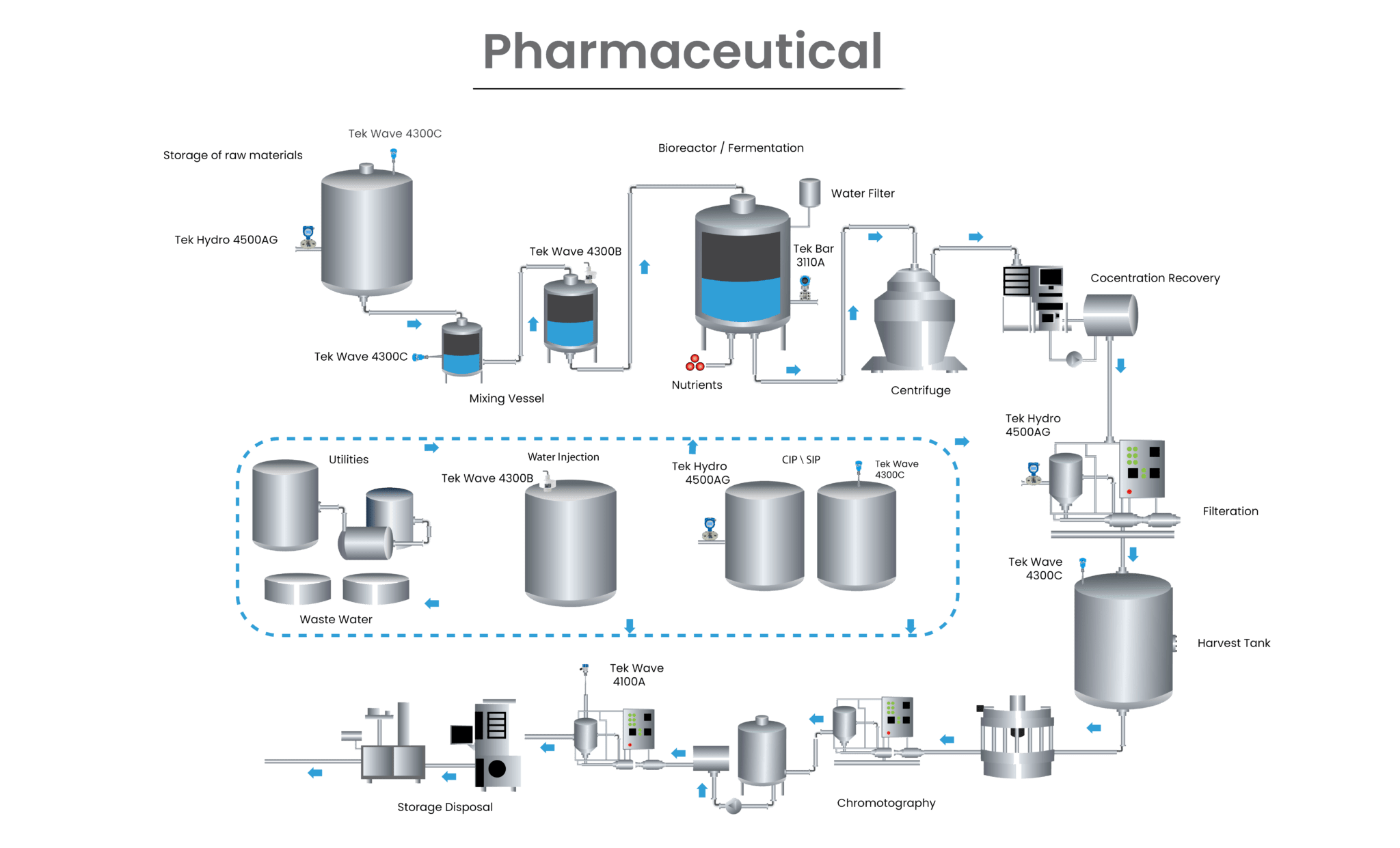

Pharmaceutical Industry Measurement & Control Solutions

We provide precise instrumentation solutions for the pharmaceutical that meet strict safety, sterility,and precision requirements. Our products include flow, level, pressure, and temperature measurement instruments for various applications. Our solutions ensure efficient and secure production processes, lower costs,and increase quality and yields while emphasizing data integrity and digital innovation to enhance efficiency and productivity, reduce time to market, and achieve operational excellence.

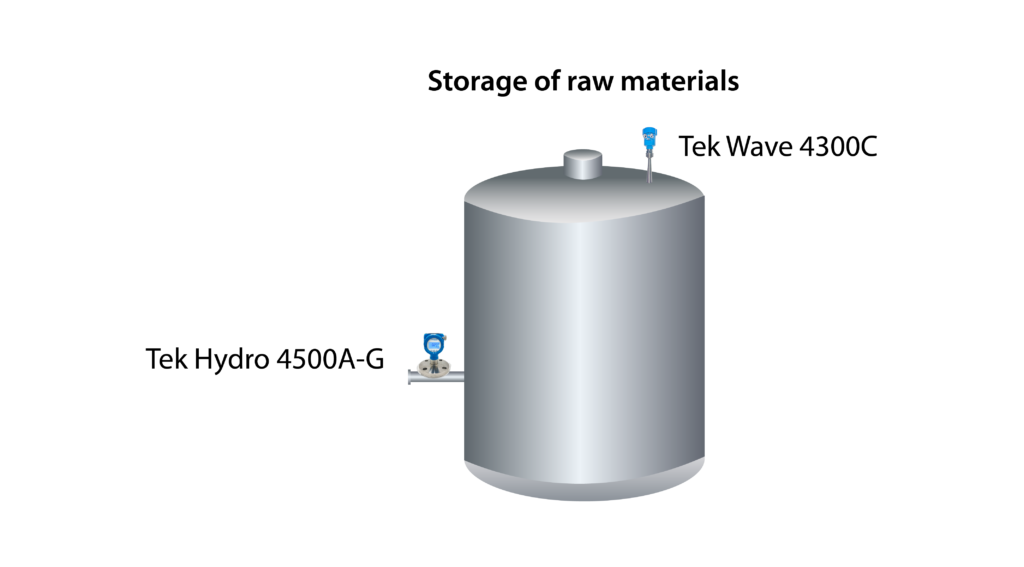

Storage of raw materials

Precise level and pressure measurements are crucial in the pharmaceutical for the safe and efficient storage and transport of raw materials. Ultraclean water used for injections, solvents, and other liquids must be carefully monitored to prevent contamination or loss. Level measurement and point level detection prevent tank damage and spillage. Accurate measurements ensure smooth production processes, minimize waste, and reduce costs. Maintaining the purity of stored materials is vital for the safety and quality of the final product. Overall, precise level and pressure measurements are critical in ensuring the pharmaceutical production process’s safety, quality, and efficiency.

- Level Measurement

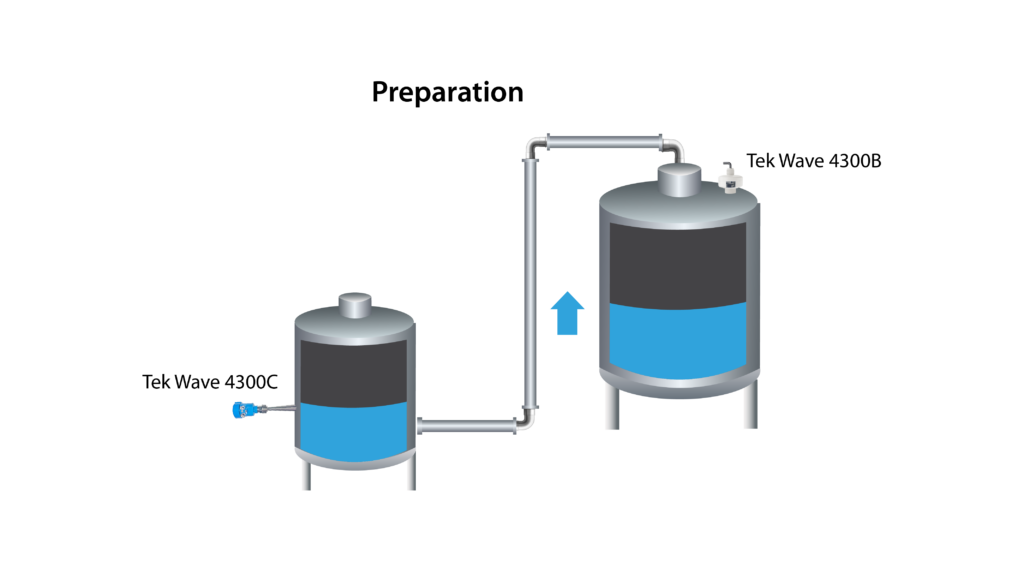

Preparation

- Level Measurement

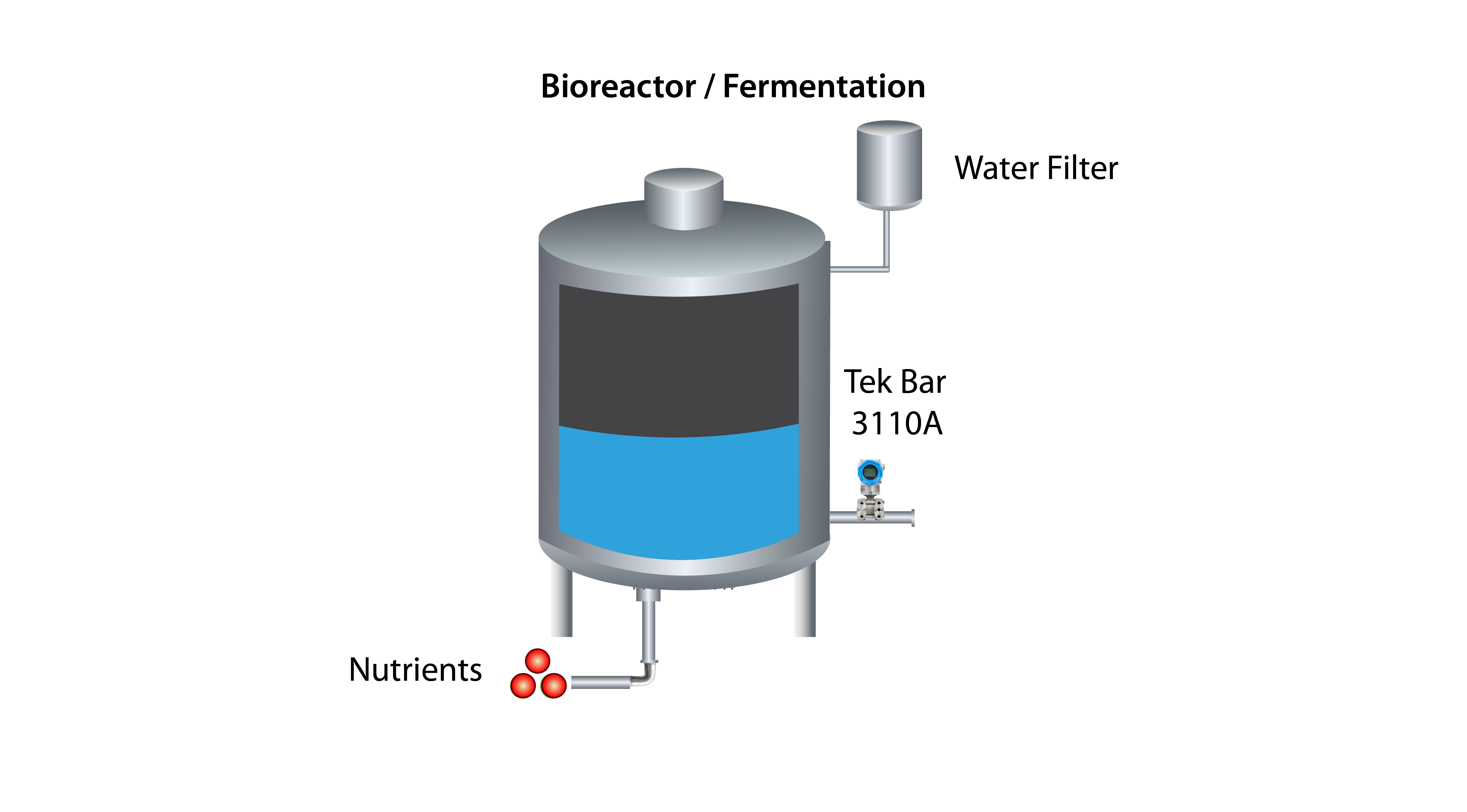

Bioreactor \ Fermentation

- Pressure Measurement

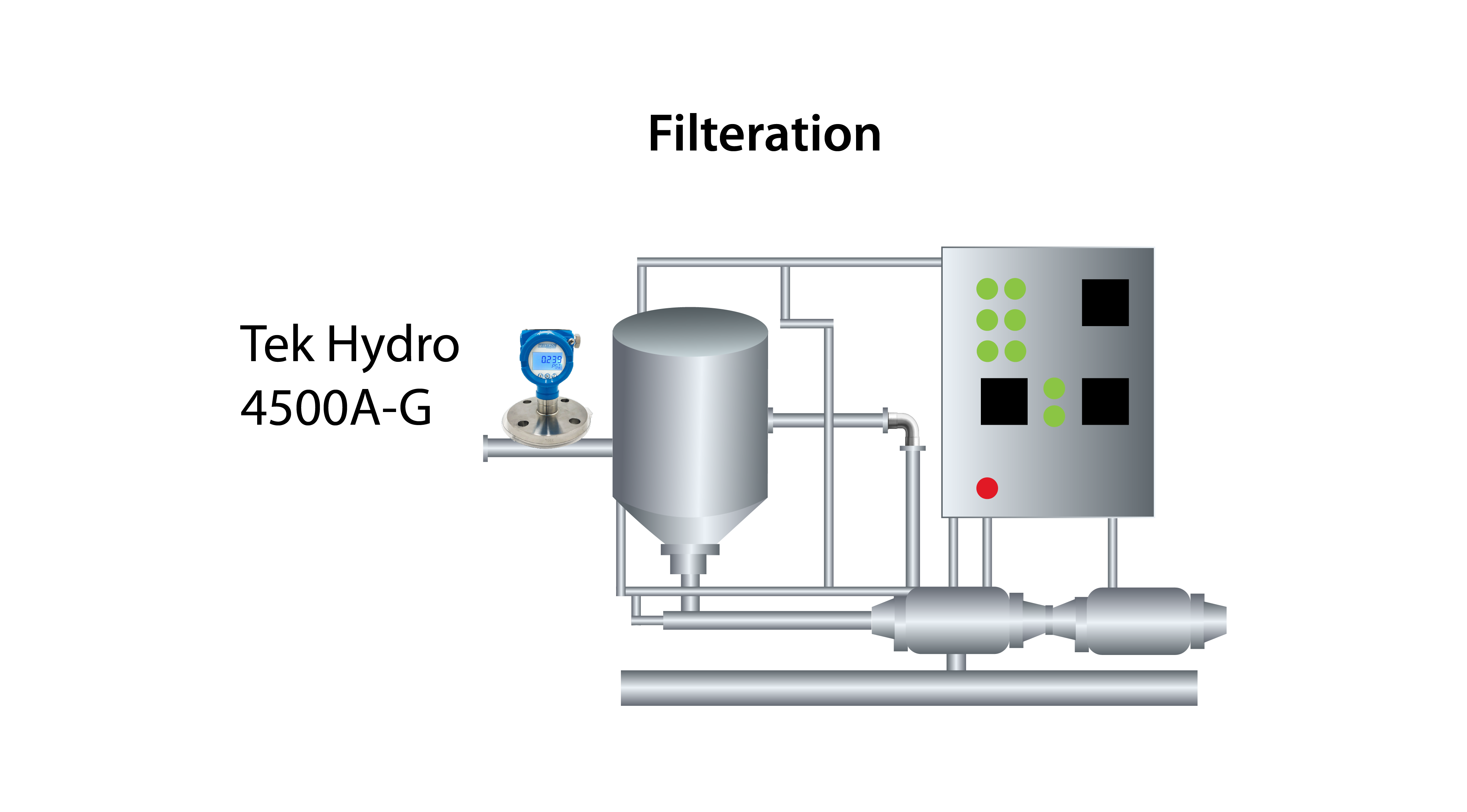

Filteration

- Level Measurement

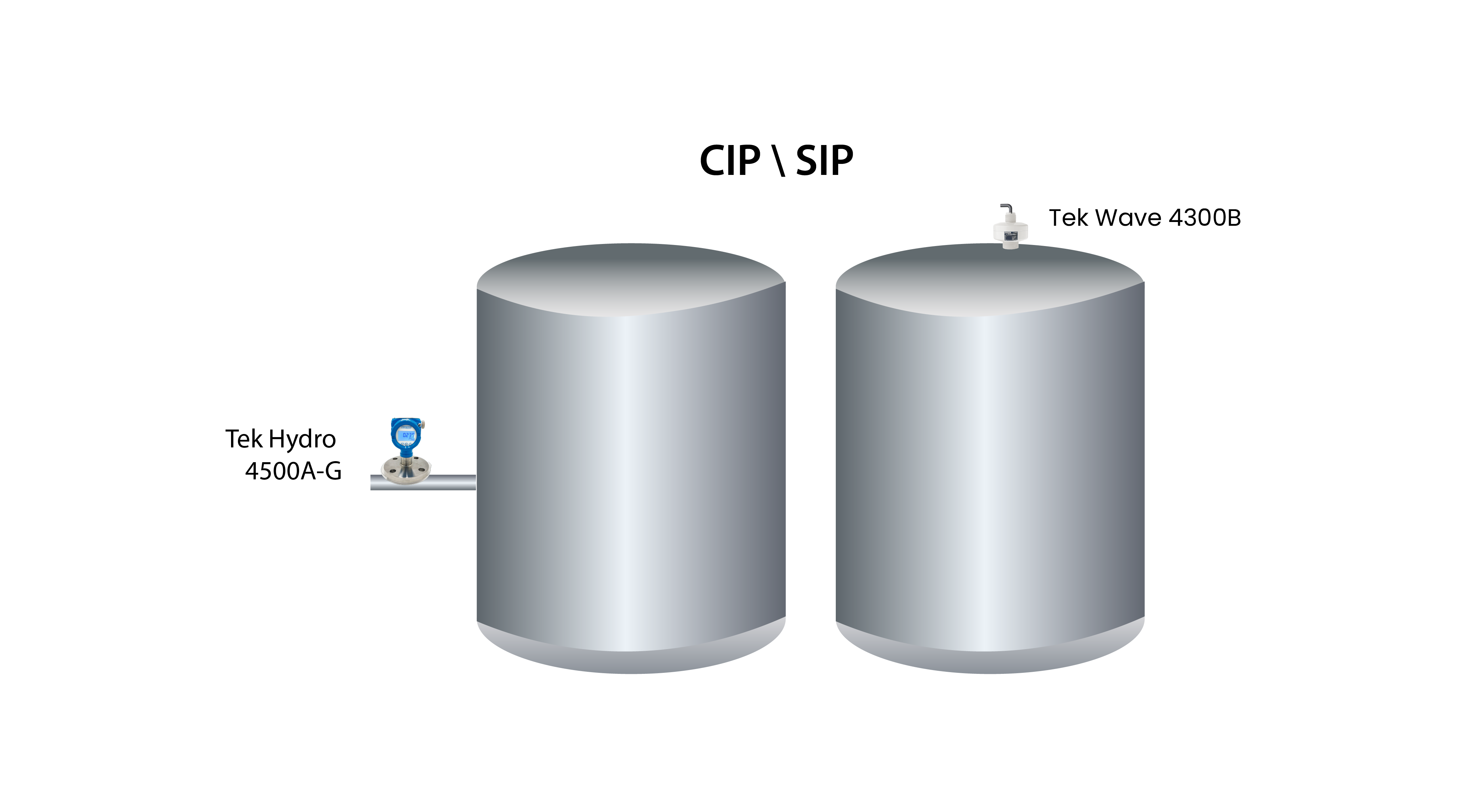

CIP/SIP

- Level Measurement

Logistics

- Level Measurement

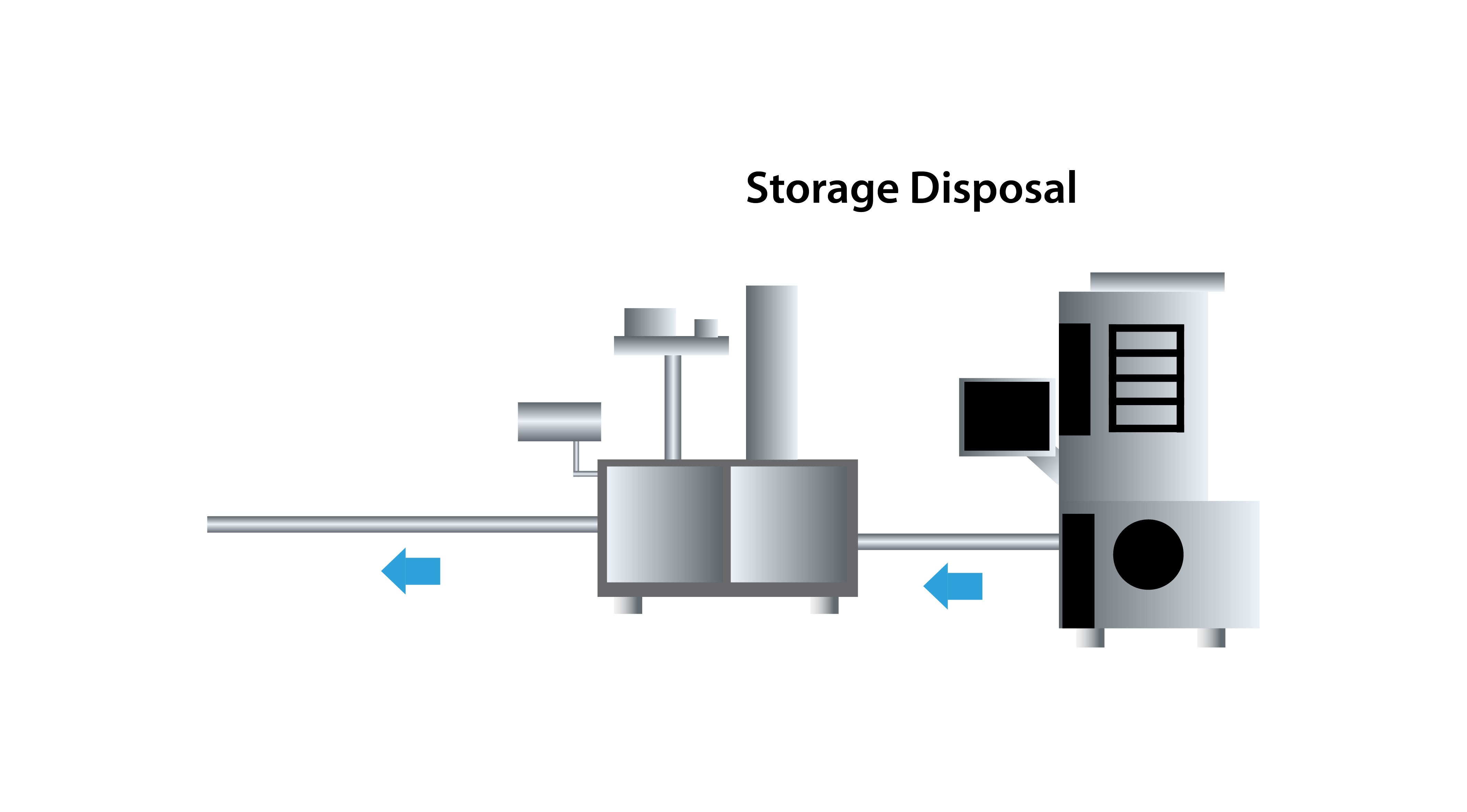

Storage Disposal

- Level Measurement