Accuracy and Uncertainty in Measurements

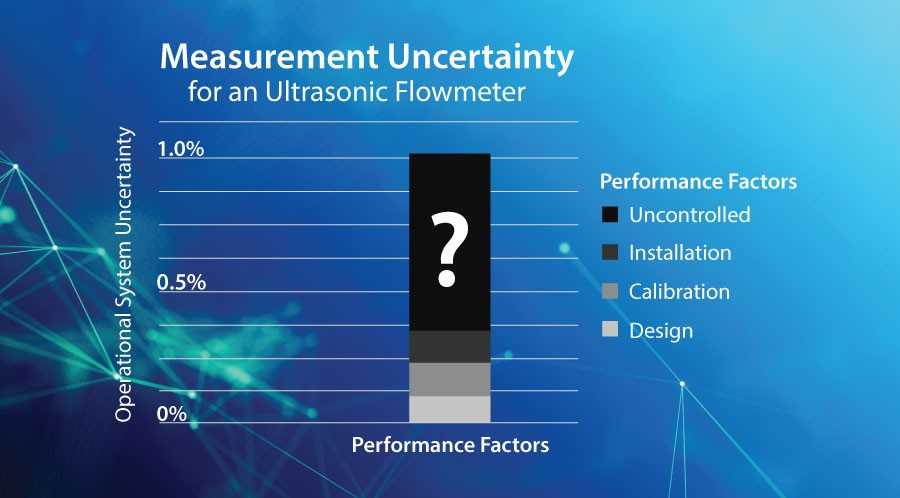

Accuracy and Uncertainty in Measurements Process control systems involve measurement of a number of parameters outcome of which is reflected in control action taken by the system. Therefore correctness of measurement has utmost importance and manufacturer of process measurement instruments is committed to ensure and provide accuracy that is claimed to be. Accuracy and uncertainty closely affect the performance but unfortunately, these terms are often used inappropriately in specifications and thus can be misguiding. Therefore, it is essential to know the reference of these terms. When mentioned in percentage it is important to know whether it is based on full scale (FS) or actual reading (AR). Let’s consider an example of the ultrasonic flow meter to understand its performance dependencies. Ultrasonic flow meters are widely used in pipe flow measurement, custody transfer, and flow survey. These meters are considered to be advantageous over conventional flow meters. The ultrasonic metering technique works on the physical characteristic of a sound wave that changes frequency when it gets reflected by particles in motion in process media. Hence, the performance of ultrasonic flow meters depends on two major factors: the nature of the process fluid and the meter’s linkage. It requires an acoustically conductive process fluid through which a sound wave can be transmitted and its reflections can be detected. Linkage of the meter is nothing but the connection between the adjacent mediums. For example, a linkage between the transducer – pipe wall, pipe wall – lining (if present) and lining – process fluid. […]