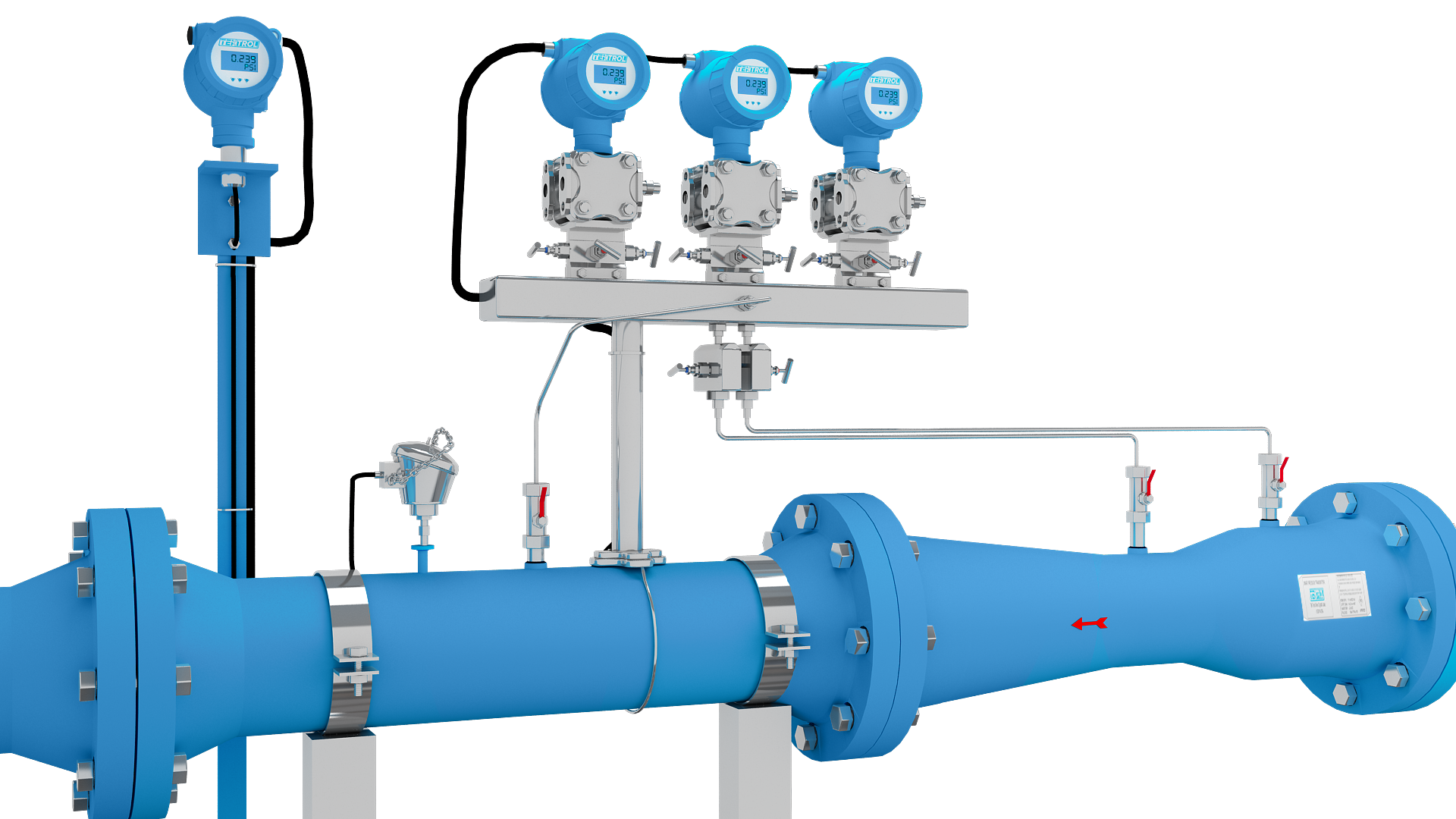

Wet Gas

Wet gas flow is defined as a gas flow that contains a small amount of liquid. It is an adverse flow condition for all flow meters and incorporates a wide range of flow conditions, where different operators require different wet gas meter capabilities.

Wet Gas Metering Applications have increased in recent years, particularly in allocation, monitoring of production, and in the move towards fiscal metering for newly developed marginal and significant gas fields. Tek-Trol’s Wet Gas Metering range is uniquely positioned to provide the operator with the optimum solution for wet-gas flow measurement, which is significantly more complicated than measuring the single-phase gas flow.

Features

Specifications

Documents

Features

- Operator Friendly

- Low Maintenance

- Predict liquid loading value

- Uses Wet Gas Correction Algorithm

- Simple and Robust

Specifications

| WET GAS ORIFICE METER SYSTEM | Sizes / Flange | Size: 2” to 48”, up to schedule 120, Flanges: #150 – #2500. |

|---|---|---|

| Meter Run Compliant | AGA 3 / API 14.3 / ISO 5167-2 orifice meter run compliant. | |

| Designs Available | Dual Chamber, Single Chamber. | |

| Wet Gas Operating Range | Liquid Loading ‘XLM’ ≤ 0.2 (≈ GVF ≥95%)150psi (10 Bar) ≤ Pressure ≤ 2500psi (83 Bar) | |

| Flow Rate Knowledge | No liquid loading or liquid flow rate knowledge required. | |

| Prediction | Gas flow prediction up to ± 3% accuracy, with liquid loading indicator | |

| WET GAS VENTURI METER SYSTEM | Sizes / Flange | Size: 2” to 48”, all standard schedule, connections and materials. |

| Meter Run Compliant | ISO 5167-4 / ISO TR 11583 Venturi meter compliant. | |

| Unit | Complete Meter run, Instrumentation, and Flow Computer unit. | |

| Applications | For use with test separator / tracer dilution estimated liquid flow or unknown liquid flow with the range of ISO TR 11583. | |

| Operating range | Operating range: As stated by ISO TR 11583 | |

| Gas flow prediction | Gas flow prediction up to ±3% accuracy, with liquid flow indicator. | |

| Validation | Option validation system ‘PrognosisTM’. | |

| WET GAS CONE METER SYSTEM | Sizes / Flange | Sizes: 2” to 48”, up to schedule XXS, Flanges #150 – #2500. |

| System | Complete Meter run, Instrumentation, and Flow Computer unit. | |

| Accuracy | Gas flow prediction up to ±3% accuracy, with liquid flow indicator. | |

| Liquid Loading Range | Liquid Loading ‘XLM’ ≤ 0.12 (≈ GVF ≥ 95%). | |

| Velocity | Minimum Inlet Gas Velocity ‘Vg’ ≥ 15 ft/s ( ≥ 5 m/s). | |

| Pressure | Pressure ≥ 150 psi ( >10 Bar). | |

| Option | Option validation system ‘PrognosisTM’. | |

| COVOR WET GAS METER | Measurement Options | Measures fluid density, volumetric flow rate and mass flow rate along with density of changing gas mixtures. |

| Advanced Diagnostic | Continuously monitor and verify the flow meter health and reduce output uncertainty using Advanced diagnostic software. | |

| Cost-Effective | Multiple readings from a single installed device reduces initial cost, installation cost and cost-of ownership over the lifetime of the instrument. | |

| Calculations | AGA-3, ISO5167, V Cone. | |

| Reliable | No moving parts, Non-contact fluid sensor. | |

| Multi-variable options | Multi-variable options available for temperature and pressure measurement. | |

| Remote Electronics Option | Use in harsh environments or locations with limited access. | |

| Mass Flow Equations | Real gas, Ideal gas, AGA 8, API 2540. | |

| HART Protocol | Modbus, BACnet, Power over Ethernet (PoE) communications available. | |

| TEK-FCA 8000A FLOW COMPUTER | Design | Flexible design with power and communication options to meet field instrument needs. |

| Compliances | Complete Meter run, Instrumentation, and Flow Computer unit. | |

| Data Logging | Real time measurement and Enhanced Data Logging capabilities. | |

| Advanced Diagnostic | Continuously monitor and verify the flow meter health and reduce output uncertainty using Advanced diagnostic software. | |

| Operator Friendly | Easy to use with multiple differential pressure like Orifice, Venturi, Flow Nozzle, Wedge, Cone. | |

| Field Configuration | Simple and easily interface with the device using push buttons. | |

| Flow Units | Volumetric or Mass flow measurement of Liquid, Gases and Steam. | |

| Calculations | AGA-3, ISO5167, V Cone | |

| Mass Flow Equations | Real gas, Ideal gas, AGA 8, API 2540 | |

| Measurement Options | Steam Quality and Density of Gas Mixture measurement. | |

| Low Power | Cost Effective, Low Power field mount flow computer. |

Documents

- Markets