Boiler House Instrumentation And Controls Industry Measurement & Control Solutions

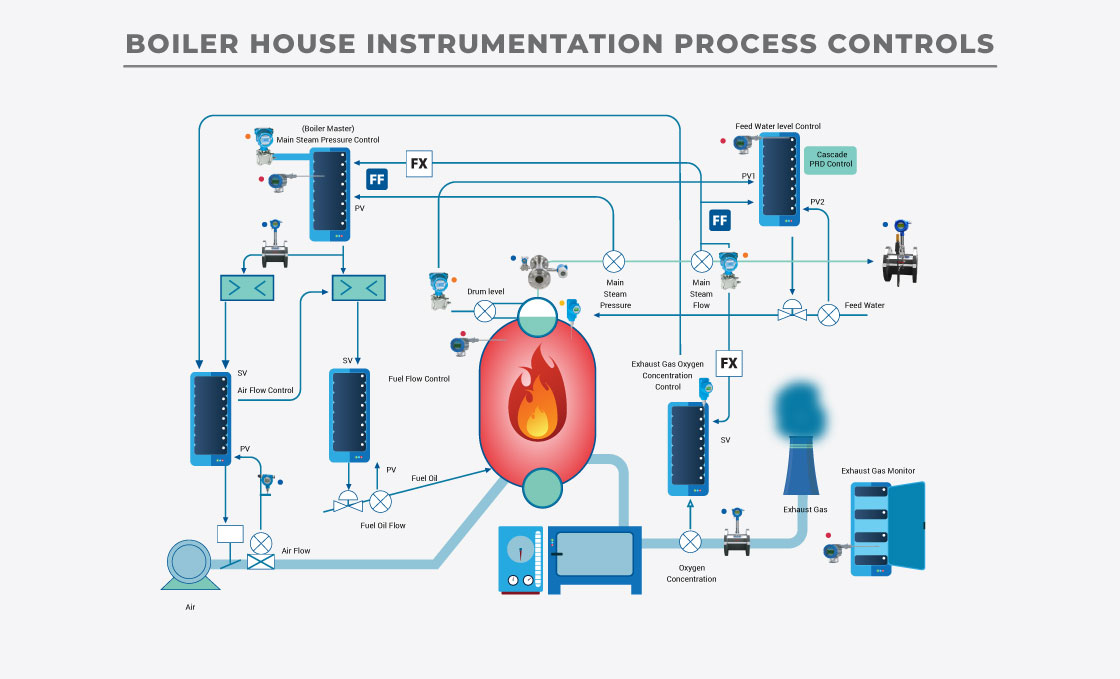

A Boiler is a closed vessel in which water or other fluid is heated. The boiler control system means a balance of energy and mass. Boilers are used in a wide range of process industries such as electric power, pharmaceuticals, chemicals, ceramics, and paper and pulp. In Most of the industries, many facts are depending on the boiler’s growth, such as rising energy costs, tightening environmental regulations, and

increasing awareness, the need for high-efficiency operation, low emission operation, and safe and stable operation. Boiler control minimizes the excess air, blow-down, steam pressure in the process plant.

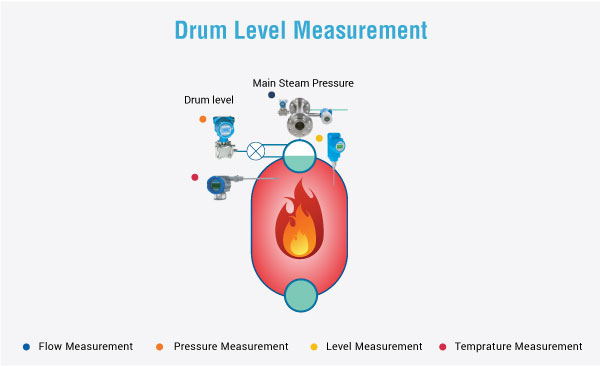

DRUM LEVEL MEASUREMENT

Drum Level Measurement system is widely used in process industries, and the utilities to control the level of boiling water in boiler drums on process plants also provide a constant supply of steam. A drum level control system controls the level of the disturbances, level change, increase or decrease of steam, and feed water flow variations.

- Flow Measurement

- Temp Measurement

- Pressure Measurement

- Level Measurement

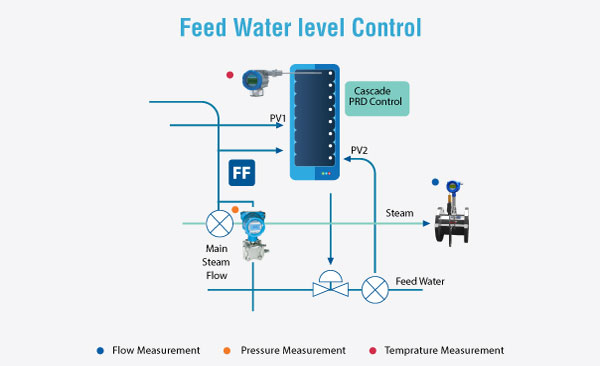

FEED WATER LEVEL CONTROL

- Flow Measurement

- Temp Measurement

- Pressure Measurement

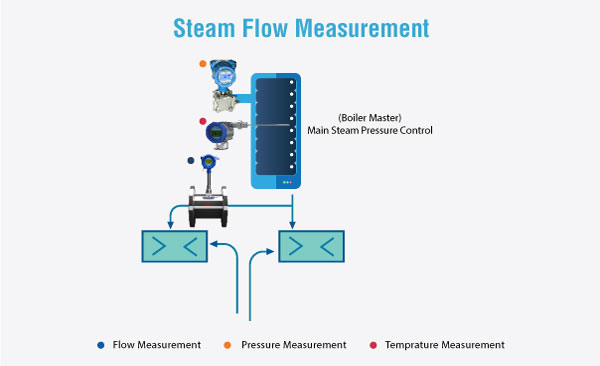

STEAM FLOW MEASUREMENT

Steam can be distributed mainly in two parts, i.e., statured and super-heated steam. Insufficient steam supply provides an incorrect process operation. Therefore, it is necessary to measure steam in process instrumentation with appropriate boiler controls and continuous flow measurement. Tek-Trol full range of flow metering and monitoring solutions provide superior efficiency in steam measurement.

- Flow Measurement

- Temp Measurement

- Pressure Measurement

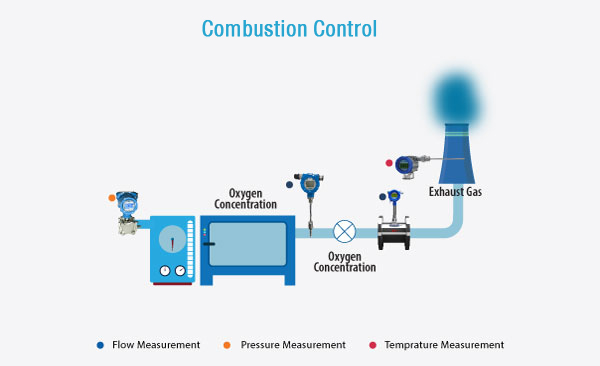

COMBUSTION CONTROL

- Flow Measurement

- Temp Measurement

- Pressure Measurement

- Level Measurement

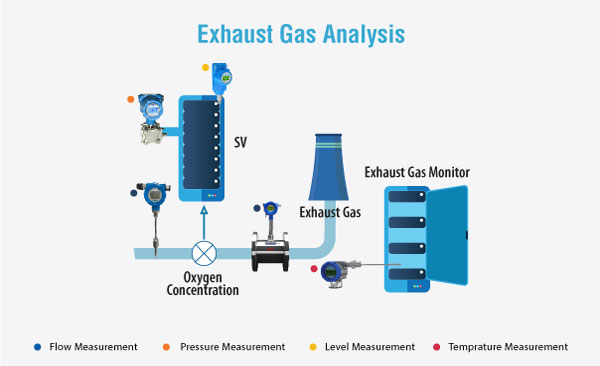

EXHAUST GAS ANALYSIS

- Flow Measurement

- Temp Measurement

- Pressure Measurement

- Level Measurement